Are you a mold remediation professional looking to ensure you have all the necessary tools and equipment for the job? Look no further! In this article, we will guide you through a comprehensive list of essential tools and equipment that every mold remediation professional should have in their arsenal. From personal protective equipment to moisture meters and air scrubbers, we’ve got you covered. So, whether you’re just starting out or looking to upgrade your toolkit, read on to make sure you have everything you need to effectively tackle mold problems and create a safe and healthy environment.

Personal Protective Equipment (PPE)

Importance of PPE

Personal Protective Equipment (PPE) is crucial in mold remediation as it ensures the safety and well-being of the professionals involved. PPE provides a barrier between you and the potentially harmful mold spores, protecting your skin, eyes, and respiratory system from exposure. By wearing the appropriate PPE, you minimize the risk of inhaling or coming into direct contact with mold, preventing any potential health issues that may arise from exposure.

Essential PPE types for mold remediation: Gloves, goggles, respirators

When it comes to PPE, there are a few essential types that should be worn during mold remediation. Firstly, gloves provide a protective barrier for your hands, shielding them from direct contact with mold and any chemicals used during the remediation process. Disposable nitrile gloves are often recommended due to their durability and resistance to chemicals.

Secondly, wearing goggles is crucial to protect your eyes from mold spores, dust, and any cleaning or disinfecting agents. Mold spores can cause irritation and allergic reactions when they come into contact with the delicate tissues of your eyes. Safety goggles with a snug fit and side shields should be worn to provide full protection.

Lastly, respirators are necessary to protect your respiratory system from inhaling mold spores. Mold spores can enter your lungs and cause respiratory issues, especially for individuals with allergies or asthma. An N95 respirator or higher-rated mask that is properly fitted and approved by the National Institute for Occupational Safety and Health (NIOSH) should be used to ensure adequate protection.

Proper use and maintenance of PPE

It is important to understand the proper use and maintenance of PPE to ensure its effectiveness. PPE should be put on before entering the mold-contaminated area and properly removed upon exiting. Gloves should be changed regularly to prevent cross-contamination.

Goggles should be cleaned with a mild detergent and warm water after each use to remove any residue or debris. Respirators should be inspected before each use to ensure they are in good condition and the filters are clean. Replace the filters as recommended by the manufacturer. Additionally, make sure to read and follow the manufacturer’s instructions for proper use and disposal of PPE to maximize its effectiveness and minimize any potential risks.

Moisture Meters

Role of moisture meters in mold remediation

Moisture meters play a crucial role in mold remediation by helping professionals identify areas of excessive moisture. These devices measure the moisture content of various materials, such as walls, ceilings, and floors. By detecting and monitoring moisture levels, professionals can accurately assess the extent of moisture damage and identify potential areas where mold growth may occur.

Types of moisture meters

There are different types of moisture meters available, each with its own specific features and applications. Two commonly used types are pin-type moisture meters and pinless moisture meters.

Pin-type moisture meters have pins that are inserted into the material being tested to measure its moisture content. They provide precise measurements and are ideal for measuring the moisture content of wood, drywall, and other building materials.

Pinless moisture meters, on the other hand, use sensors to detect moisture without causing any damage to the material. They are suitable for measuring moisture levels on surfaces and are especially useful for larger areas.

Factors to consider when choosing moisture meters

When selecting a moisture meter for mold remediation, there are several factors to consider. Accuracy and reliability are key, so choose a moisture meter that provides consistent and precise readings. Additionally, consider the meter’s measurement range, as some may have limitations when it comes to detecting moisture in certain materials.

Ease of use and portability are also important factors to consider. Look for a moisture meter that is user-friendly and lightweight, allowing for easy maneuverability in tight spaces. Lastly, consider the price and warranty of the moisture meter, ensuring it fits within your budget and comes with reliable customer support.

Infrared Cameras

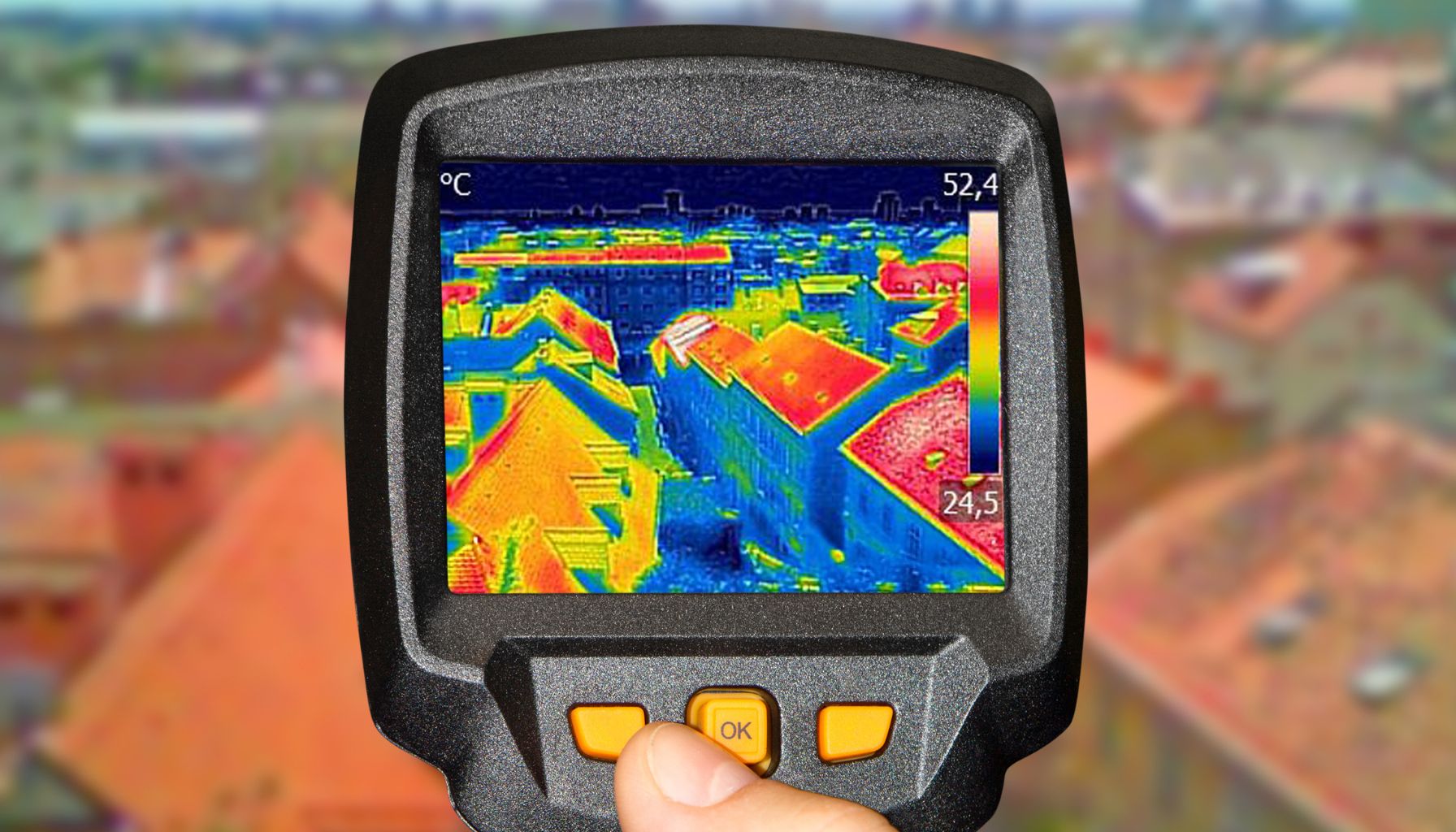

Use of infrared cameras in detecting mold

Infrared cameras are valuable tools in mold detection as they utilize thermal imaging technology to identify areas of temperature variation. Mold growth often causes changes in temperature due to increased moisture, and these temperature differences can be detected by infrared cameras. By capturing images that display temperature variations, professionals can pinpoint potential mold growth areas behind walls, ceilings, and other surfaces.

Types of infrared cameras suitable for mold remediation

There are various types of infrared cameras suitable for mold remediation, including thermal imaging cameras and moisture-seeking infrared cameras. Thermal imaging cameras capture images based on the heat signatures emitted by objects, enabling professionals to detect temperature anomalies that indicate moisture and potential mold growth.

Moisture-seeking infrared cameras are specifically designed to identify areas with excessive moisture content. This type of camera can be especially useful in locating leaks, water intrusion, and hidden moisture sources that may contribute to mold growth.

How to effectively use infrared cameras in mold detection

To effectively use infrared cameras in mold detection, it is important to follow proper techniques and guidelines. Firstly, ensure that the area being scanned is at a stable temperature and free from any external heat sources that may interfere with the accuracy of the readings.

Secondly, carefully scan the surfaces, focusing on areas where moisture problems are suspected. Look for temperature variations and anomalies that may indicate hidden mold growth. It is also beneficial to compare the thermal images with visual inspection findings to confirm and accurately identify potential mold sources.

Lastly, interpret the infrared images with caution and seek professional guidance if you are unsure about the findings. Remember that infrared cameras are just tools, and their results should be validated and verified through proper mold testing procedures.

Air Scrubbers

Purpose of air scrubbers in mold remediation

Air scrubbers play a vital role in mold remediation by removing airborne mold spores and other contaminants from the air. Mold spores can become airborne during the remediation process, posing a health risk to individuals in the vicinity. Air scrubbers help capture and filter out these spores, preventing their spread to unaffected areas and minimizing the chance of cross-contamination.

Choosing the right air scrubber

When selecting an air scrubber for mold remediation, it is important to consider its filtration capabilities and efficiency. Look for air scrubbers with high-efficiency particulate air (HEPA) filters, as these filters are designed to capture tiny particles, including mold spores.

Additionally, consider the size and capacity of the air scrubber. Ensure that it can effectively handle the volume of air in the space being remediated. The air scrubber should be able to provide sufficient air exchanges per hour to effectively remove airborne contaminants.

Proper utilization of air scrubbers in mold remediation

To effectively use air scrubbers in mold remediation, it is important to strategically place them in the affected area. Position the air scrubber near the contamination source to capture mold spores before they have a chance to spread. Additionally, place air scrubbers in areas where there is a high concentration of mold spores, such as near damaged materials or areas with visible mold growth.

Regularly monitor the air scrubber’s filter and change it as needed to maintain optimal performance. Follow the manufacturer’s recommendations for maintenance and cleaning to ensure the air scrubber operates efficiently throughout the remediation process.

HEPA Vacuums

Significance of HEPA vacuums in mold remediation

HEPA vacuums are essential tools in mold remediation as they effectively remove mold spores and other particles from surfaces and the air. Regular vacuums with standard filters may not have the capability to capture microscopic mold spores, potentially leading to their release back into the air and causing further contamination. HEPA vacuums, however, are equipped with high-efficiency particulate air filters that can trap and contain these tiny particles.

Choosing the right HEPA vacuum

When choosing a HEPA vacuum for mold remediation, consider its filtration efficiency and durability. Look for a vacuum that has been specifically designed for mold remediation purposes and has been tested and certified to meet HEPA filtration standards.

Additionally, consider the vacuum’s suction power and attachments. A powerful vacuum with various attachments can help effectively clean different surfaces and hard-to-reach areas. The vacuum’s capacity is also important, as it should be able to hold a sufficient amount of debris without frequent emptying.

Proper use and maintenance of HEPA vacuums

Proper use and maintenance of HEPA vacuums are crucial to ensure their effectiveness in mold remediation. Before using the vacuum, ensure that all attachments are properly connected and the vacuum is in good working condition. Empty and clean the vacuum’s collection container regularly to prevent the accumulation of mold spores and debris.

Inspect the HEPA filter before each use to ensure it is clean and functioning properly. Replace the filter as recommended by the manufacturer to maintain optimal filtration efficiency. Lastly, store the HEPA vacuum in a clean and dry area to prevent any potential mold contamination.

Dehumidifiers

Role of Dehumidifiers in mold remediation

Dehumidifiers play a significant role in mold remediation by reducing moisture levels in the air. Mold thrives in environments with high humidity, so by using dehumidifiers, you can effectively control and reduce the moisture content in the affected area. Dehumidifiers extract excess moisture from the air, inhibiting the growth and spread of mold.

Different types of dehumidifiers

There are various types of dehumidifiers available, including refrigerant dehumidifiers, desiccant dehumidifiers, and whole-house dehumidifiers. Refrigerant dehumidifiers work by cooling the air, causing moisture to condense and collect in a reservoir. These dehumidifiers are commonly used for residential and smaller-scale mold remediation projects.

Desiccant dehumidifiers, on the other hand, use a desiccant material to absorb moisture from the air. These dehumidifiers are often used in industrial or commercial settings where large volumes of moisture need to be removed.

Whole-house dehumidifiers are integrated into the HVAC systems of buildings and provide moisture control for the entire space. These dehumidifiers are ideal for large-scale mold remediation projects or high-humidity areas.

Factors to consider when selecting dehumidifiers

When selecting dehumidifiers for mold remediation, consider the size and capacity of the dehumidifier, as well as the specific moisture removal needs of the space. Calculate the square footage of the area to be dehumidified and choose a dehumidifier that can effectively handle the required moisture extraction.

Additionally, consider the energy efficiency and noise level of the dehumidifier. Look for Energy Star-rated dehumidifiers that are designed to consume less energy while still providing effective moisture control. Noise level is also important, especially if the dehumidifier will be used in occupied spaces or during working hours.

Mold-Fighting Chemicals

Importance of mold-fighting chemicals

Mold-fighting chemicals are essential in mold remediation as they help kill and prevent the growth of mold spores. These chemicals are specifically formulated to target mold and can be used to treat affected surfaces or materials. Mold-fighting chemicals not only eliminate existing mold but also act as a preventive measure against future mold growth.

Examples of effective chemicals for mold remediation

There are several effective mold-fighting chemicals available, including hydrogen peroxide, borax, and antimicrobial sprays. Hydrogen peroxide is known for its ability to kill mold spores on contact and is safe to use on various materials. Borax, a natural mineral, also kills mold spores and prevents their future growth. Antimicrobial sprays can be used for surface treatment and provide a protective barrier against mold.

It is important to note that when using mold-fighting chemicals, always follow the manufacturer’s instructions and safety guidelines. Wear appropriate PPE to protect yourself from any potential risks.

Safety measures when handling mold-fighting chemicals

When handling mold-fighting chemicals, it is important to take proper safety measures. Always wear gloves, goggles, and a respirator to protect your skin, eyes, and respiratory system from the chemicals. Make sure to work in a well-ventilated area to minimize exposure to fumes.

Read and follow the manufacturer’s instructions for proper dilution and application of the chemicals. Avoid mixing different chemicals together, as this can lead to hazardous reactions. Diligently follow disposal guidelines for any chemical waste generated during the remediation process.

Containment Barriers

Use of containment barriers in preventing spread of mold

Containment barriers are crucial in mold remediation as they help prevent the spread of mold spores to unaffected areas. These barriers create a physical separation between the work area and the rest of the building, isolating the mold-contaminated area and containing the mold spores within it. By establishing containment barriers, you minimize the risk of cross-contamination and ensure that mold remediation activities do not further spread the mold.

Types of containment barriers

There are different types of containment barriers that can be used in mold remediation, including polyethylene sheeting, zip walls, and negative air machines. Polyethylene sheeting is a commonly used barrier material that is durable, lightweight, and easy to install. It can be taped or sealed to floors, walls, and ceilings to create a containment area.

Zip walls provide a more flexible and adjustable option for containment barriers. These walls consist of telescoping poles and plastic sheeting with zipper access, allowing for easy entry and exit without compromising the integrity of the containment area.

Negative air machines, also known as air scrubbers with negative pressure, are used in conjunction with containment barriers to create a controlled airflow system. These machines draw air from the containment area and filter it, effectively removing and containing mold spores.

Proper setup of containment barriers

Proper setup of containment barriers is essential to ensure their effectiveness. Begin by sealing off the work area with polyethylene sheeting, ensuring that it is securely attached to the walls, floors, and ceiling. Use tape or adhesive to create an airtight seal to prevent any air or mold spores from escaping.

If using zip walls, set up the telescoping poles and attach the plastic sheeting, making sure to properly seal the top, bottom, and sides. This will create a secure barrier while allowing for easy access in and out of the containment area.

Lastly, set up negative air machines at appropriate locations within the containment area. These machines should be equipped with HEPA filters and connected to ducting that exhausts the air outside the building or through a designated air filtration system.

Mold Testing Kits

Role of mold testing kits in mold detection

Mold testing kits are valuable tools in mold detection as they allow professionals to collect samples for further analysis. These kits typically consist of swabs, cassettes, or air sampling devices that can be used to collect mold samples from different surfaces or from the air. The samples are then sent to a laboratory for analysis, where the type and concentration of mold can be determined.

Types of mold testing kits suitable for mold remediation

There are different types of mold testing kits available, each with its own specific applications. Swab kits are commonly used to collect samples from visible mold growth on surfaces. The swab is rubbed on the moldy surface, and the collected sample is then sent for analysis.

Air sampling kits use specialized devices to capture airborne mold spores. These kits are useful in situations where mold may not be visible but suspected due to a musty odor or allergy symptoms. The air sampling device is operated for a specific duration in the desired area, and the collected sample is sent to the laboratory for analysis.

How to correctly use mold testing kits

To correctly use mold testing kits, carefully follow the instructions provided by the manufacturer. Ensure that the sampling area is clean and properly prepared before collecting the samples. For surface samples, use the swab provided, ensuring it comes into direct contact with the moldy area without touching any other surfaces.

For air samples, follow the instructions on the air sampling device to set up and operate the device correctly. Place the device in the desired location and allow it to capture sufficient air samples. Make sure to avoid any interference, such as opening doors or windows during the sampling process.

After collecting the samples, carefully seal them in the provided containers or bags and send them to a certified laboratory for analysis. The laboratory will provide you with the results, including the type and concentration of mold detected.

Fogging Machines

Importance of fogging machines in mold remediation

Fogging machines are essential in mold remediation as they allow professionals to apply mold-fighting chemicals in hard-to-reach areas and on larger surfaces. These machines disperse the mold-fighting chemicals in the form of a fog, ensuring uniform coverage and maximum penetration into porous surfaces. Fogging is particularly useful for treating large spaces or areas with extensive mold contamination.

Choosing the right fogging machine

When choosing a fogging machine for mold remediation, consider the type of fogging technology it utilizes. There are several types of fogging machines available, including thermal foggers, cold foggers, and electrostatic foggers.

Thermal foggers use heat to convert mold-fighting chemicals into a fog-like vapor. They are effective in treating large areas and provide deep penetration into porous materials. Cold foggers, on the other hand, use a high-pressure system to disperse the chemicals as fine droplets. Cold foggers are versatile and suitable for both indoor and outdoor use.

Electrostatic foggers apply an electrostatic charge to the mold-fighting chemicals, allowing them to adhere to surfaces more effectively. These foggers create a fine mist that wraps around objects and provides even coverage.

Consider the coverage area, capacity, and maintenance requirements of the fogging machine when making your selection. Additionally, ensure that the fogging machine is compatible with the mold-fighting chemicals being used.

Proper use and maintenance of fogging machines

Proper use and maintenance of fogging machines are crucial to ensure their optimal performance. Before using the fogging machine, read and follow the manufacturer’s instructions for safe operation. Make sure to wear appropriate PPE, including gloves, goggles, and a respirator, during the fogging process to protect yourself from exposure to mold-fighting chemicals.

Clean the fogging machine thoroughly after each use to prevent any residual chemicals from causing damage or affecting future applications. Follow the manufacturer’s guidelines for maintenance and cleaning, and store the fogging machine in a clean and dry area to prolong its lifespan.

In conclusion, personal protective equipment (PPE), moisture meters, infrared cameras, air scrubbers, HEPA vacuums, dehumidifiers, mold-fighting chemicals, containment barriers, mold testing kits, and fogging machines are all essential tools and equipment for mold remediation professionals. Each of these items plays a specific role in detecting, containing, and effectively eliminating mold growth. By understanding the importance and proper usage of these tools, professional mold remediation services can ensure a safe and thorough mold remediation process, protecting both their own health and the overall well-being of the affected environment.